Zinc Plating

At Paramount Plating we operate one fully automatic rack zinc plating plant with a maximum process window of 3.6m x 1.5m x 0.6m. One large automatic barrel process plants with 1.2m cylinders. The process solutions are Acid based which produces a very shiny decorative finish with either Clear or Colour passivation available. Our plants have fully automated transporters with a high degree of process control, which includes automatic dosing of process chemicals and additives as well as process solution temperature and direct current control.

Benefits

Zinc is the process of choice for a cost effect method of achieving enhanced corrosion protection. It is also an ideal sub-surface for final finishing.

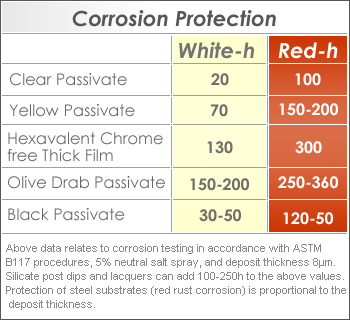

Corrosion Protection

Corrosion protection is directly proportional to the electroplate thickness (3-30µm according to our client's specification). The principal protection is due to the zincs encasement of the item, which prevents contact with the environment.

An important feature of zinc is it’s sacrificial property, which means that where the ferrous base of the item is exposed to humidity for example, the associated chemical reactions of corrosion will affect the zinc in preference to the steel. Zinc also provides outstanding metal distribution and uniform covering power.

The coating is capable of accepting the environmentally friendly clear blue trivalent chromium passivate as well as yellow and olive drab finishes.

Wear Protection

Zinc plating bestows an increased surface hardness on the item with the finished hardness (100g HV) ranging between 80-150HV. Zinc is beneficial where items must retain their original appearance for many years.

Value Added Services

Zinc plating can be used as a final finish or as a base for post-treatments. Additional treatments can be applied to complement the primary finish such as clear or coloured lacquering, oil seals, wax silicate finishes, leach and seal systems or wax emulsions dosed with corrosion inhibitors. Post treatment applications can be applied for functional or aesthetic purposes.

Metal finishing processes are subject to strict environmental control. Our purpose built plant uses the latest technology... Click Here to Read More.

Paramount Plating Ltd. is WEEE & RoHS compliant and offer suitable alternatives for both Lead and Hexavalent Chromium compounds... Click Here to Read More.